Isodyne Connector Backshells

101 Series Circular Backshells

ISO 101 ( REV. D ) Series EMI/RFI MIL spec circular connector backshells are light weight, economical, and saves space by eliminating the rotating coupling nut. The slot and boot groove are optional providing faster lead times and lower cost. Some connector interfaces include, but are not limited to: MIL-C-5015, MIL-C-26482, D38999 Series I, II, III, IV.

View Backshells

135 Series Circular Backshells

ISO 135 SERIES ( REV. Q ) EMI/RFI circular connector backshells are a miniaturized, small, lightweight backshell solution that interfaces with Glenair 800, 801, 803, 804 & 805 Mighty Mouse connectors.

View Backshells

150 Series Circular Backshells

Our ISO 150 Series (REV. AF) EMI/RFI circular connector backshells offer a single banding surface. Interfaces with MIL 26482, D38999 Series I,II,III,IV and more. Available in straight, 45 and 90 degree angular functions and Military MIL spec. Superior EMI protection for military and commercial application.

View Backshells

151 Series Circular Backshells

ISO 151 SERIES ( REV. H ) EMI/RFI circular connector backshells are a direct couple backshell for connector designator B MIL-C-5015 MS3100 series connectors as well as connector designator D MIL-C-26482 Series I backshells.

View Backshells

155 Series Circular Backshells

ISO 155 SERIES ( REV. K ) EMI/RFI circular connector backshells offer a single banding surface and a Quick-Tie strain relief. They are available in straight, 45 and 90 degree angular functions. Interfaces with MIL-C-26482, D38999 Series I,II,III,IV and more.

View Backshells

160 Series Circular Backshells

ISO 160 SERIES ( REV. K ) EMI/RFI circular connector backshells offer two banding surfaces for double gross over braid requirements. It is available in straight, 45 and 90 degree angular functions and in reverse bayonet. They interface with MIL-C-26482, D38999 Series I,II,III,IV and more.

View Backshells

165 Series Circular Backshells

ISO 165 SERIES ( REV. K ) EMI/RFI circular connector backshells are similar to our 160 series while adding Quick-Tie strain relief. These are available in straight, 45 and 90 degree angular functions and in reverse bayonet coupling. They interface with MIL-C-26482, D38999 Series I,II,III,IV and more.

View Backshells

170 Series Circular Backshells

ISO 170 SERIES ( REV. E ) EMI/RFI connector backshell is a low profile, two piece design with a single banding platform. The two piece design allows for easier repair service in the field while the low profile offers additionally space savings over our standard back shells. They interface with MIL-C-26482, D38999 Series I,II,III,IV and more.

View Backshells

180 Series Circular Backshells

ISO 180 SERIES ( REV. K ) EMI/RFI circular connector backshells are a low profile hinged solution that allows easy access to the pins for field repair service with direct access to pins and contacts. Particularly beneficial when using high pin count connectors to allow ease of routing wires in the back shell. They are compatible with MIL-C-26482, D38999 Series I,II,III,IV and more. Available in Straight, 45, & 90 degree E.W.I.S. Solutions.

View Backshells

191 Series Circular Backshells

ISO 191 SERIES ( REV. J ) EMI/RFI circular connector backshells are our hinged low profile backshell with an elliptical cable entry, allowing for easy repair/service in the field with direct access to pin contacts and wires. They interface with MIL-C-26482, D38999 Series I,II,III,IV and more. Available in 90 degree cable entry only. E.W.I.S. Solutions.

View Backshells

200 Series D-Sub Backshells

ISO 200 SERIES ( REV. R ) EMI/RFI D-sub connector backshells are a D-Subminiature available in top, end and side entry, three piece construction, split access design. Higher EMI/RFI Rating. Interfaces with MIL-C-24038 connector series.

View Backshells

205 Series D-Sub Backshells

ISO 205 SERIES (REV. AB) EMI/RFI D-Subminiature (D-sub) connector backshells interface with MIL-C-24308, M24308 series connectors standard pin layouts. Available in straight, 45 and 90 degree cable entry.

View Backshells

206 Series D-Sub Backshells

ISO 206 Series ( REV. D ) EMI/RFI D-sub connector backshells are a two piece construction D-subminiature for ease of access for layout and rework which also allows this adapter to be assembled after testing. Interfaces with MIL-C-24038 connector series.

View Backshells

207 Series D-Sub Backshells

ISO 207 SERIES ( REV. Q ) EMI/RFI D-sub connector backshells are an elliptical D-subminiature for higher density cables. Available in straight, 90 and 45, Compliments MIL-C-24308 connectors and standard pin layouts.

View Backshells

215 Series Micro D-Sub Backshells

ISO 215 SERIES (REV. Q) EMI/RFI Micro D-Subminiature (Micro D-sub) connector backshells interface with MIL-C-83513 series connectors standard pin layouts. Available in straight, and 90-degree cable entry.

View Backshells

315 Series Micro D-Sub Backshells

ISO 315 SERIES (REV. A) EMI/RFI Micro D-Subminiature (Micro D-sub) connector backshells interface with MIL-C-83513 series connectors standard pin layouts. Available in straight, and 90-degree cable entry, and 45-degree cable entry.

View Backshells

ARINC Backshells

Isodyne supplies a wide variety of ARINC EMI/RFI connector backshells designed to meet specific customer requirements. Innovative solutions such as our patented hinge technology allows easy access for assembly, re-pin or repair without the need for any tools while maintaining full EMI integrity. Variable Port cable entry thread into the back plate allowing for ease of incorporating various cable diameters to a common EMI back shell. Let our engineers develop a solution that fits exactly what you need to save time, weight or space in your design.

View Backshells

Bulkhead Backshells

Bulk head connector backshells can often replace a connector used as a junction point saving weight and cost.

View Backshells

ISRA Circular Series Backshells

ISRA Series – Our Integrated Strain Relief Adapter (ISRA) is simple a modification code available on most circular cable entries, 250 inch diameter or larger. Providing strain relief directly to the cable bundle adds a level of reliability in the most rugged of applications. Reduced component count, smaller size, all FOD captured in over boot also provide improved seal ability.

View Backshells

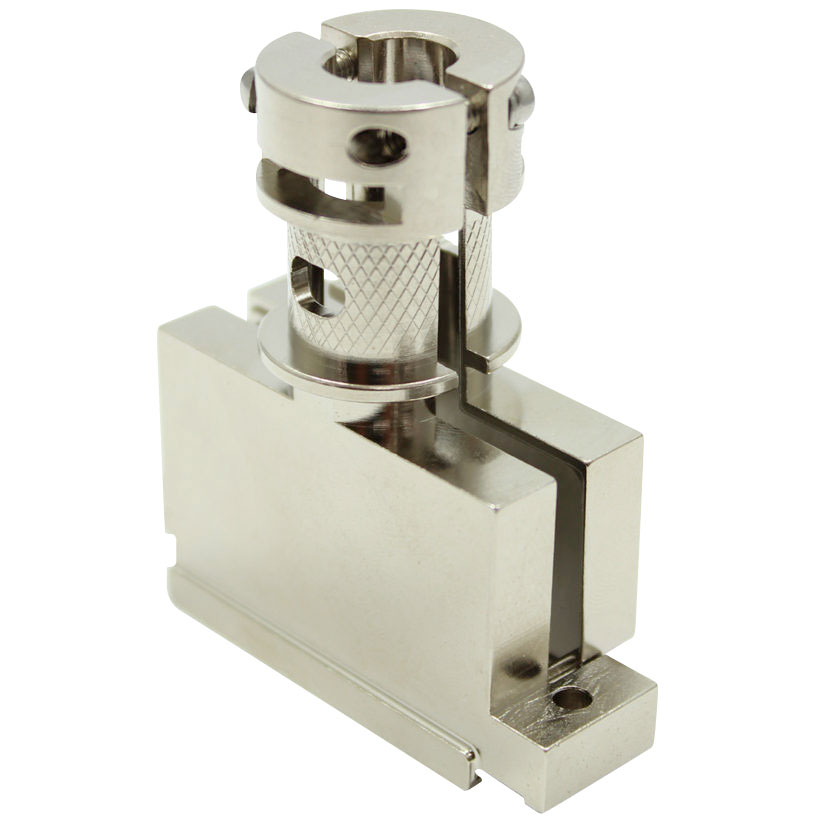

RJ45 Series Circular Backshells

Isodyne’s RJ45 backshell provides EMI shielding and protection for COTS RJ45 connectors both shielded and non-shielded. Set screws on each side of the backshell are used to hold the connector in place and provide a grounding path to the connector shield.

View Backshells

Shorting Cap Backshells

Protect your backshell connectors from debris when not in use. Variable body and lanyard lengths to best fit your application.

View Backshells

Splice Kit Backshells

Isodyne Splice kit backshells allow easy access for breakouts making assembly and repair easier, faster with increased reliability. Isodyne offers a wide variety of splice kits X, Y, T and straight backshell configurations that can be easily modified to your cable diameter needs.

View Backshells

Super Short Circular Backshells

Isodyne Super Short circular backshell adapter is one of the smallest EMI backshells available. Direct coupling to the connector reduces stack up allowing for smaller, lighter over molds. A lower cost backshell option with excellent reliability and EMI performance. Available in all plating options.

View Backshells